COMPOSITE MATERIALS REVOLUTION: CARBON FIBER ITEMS YOU’D NEVER THOUGHT OF!

Carbon fiber items no longer concern only the most technical sectors, but more and more frequently we find them also in “everyday” products. In fact, thanks to their exceptional features, composite materials are well suited to be used in the most different industrial sectors.

When we talk about carbon fiber, planes are the first thing we think about.

In fact this material is widely used in the aerospace industry thanks to its high resistance opposed to low weight, which give exceptional mechanical performance. However, its use does not stop at high-tech sectors, such as aeronautics or automotive. In recent years, carbon fiber items are increasing their popularity in everyday life.

For fans of technology and innovation, having at home carbon fiber objects is a must. Not only for the technical benefits, but above all for the exclusive aesthetic value.

The unique carbon look finish will be difficult to replicate with other materials; adding to this the almost indestructibility of the object, then it is easy to understand the appeal that such pieces can have towards a demanding consumer.

Which are the possible application fields of carbon fiber? Basically all!

Carbon fiber is suitable to realize every kind of objects, from sport equipment to bags; from table stuff to bathroom accessories.

One of the weird thing , for example, is the carbon fiber helmet “STORMTROOPER“, produced as a exclusive gadget for fans of Star Wars, in occasion of VIIth episode.

Total black lovers – even in the toilette – can’t do without a beautiful bathtub or WC made out of carbon fiber.

Even at the table carbon fiber is appropriate to amaze friends for dinner. Whether they are sushi chopsticks, coasters, or ceramic-carbon craft containers, the surprise effect is guaranteed.

Sport sector, as well, has been touched by this revolution. Carbon fiber is used in the most technical sports equipment to increase performance.

One example is horse riding saddles. The most innovative producers are progressively replacing the traditional wooden saddle tree ( the inner rigid part) with a carbon one, gaining lots of benefits in terms of resistance, elasticity and moldability.

And to never give up the exclusivity of carbon fiber, why not take it with you even while traveling?

Polycarbonate and ABS are no longer enough. The suitcases of the future will be made out of carbon fiber . Ultra lightweight but very resistant to shocks and stresses, very common especially when traveling by plane.

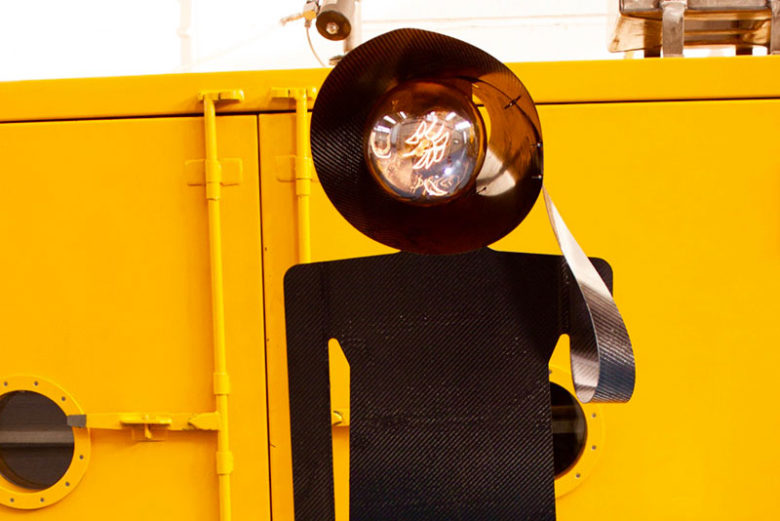

And still , eyeglasses, business cards, money clips, bags, walking sticks, watches. The list could run endlessly, demonstrating how this incredible material fits perfectly with every use.

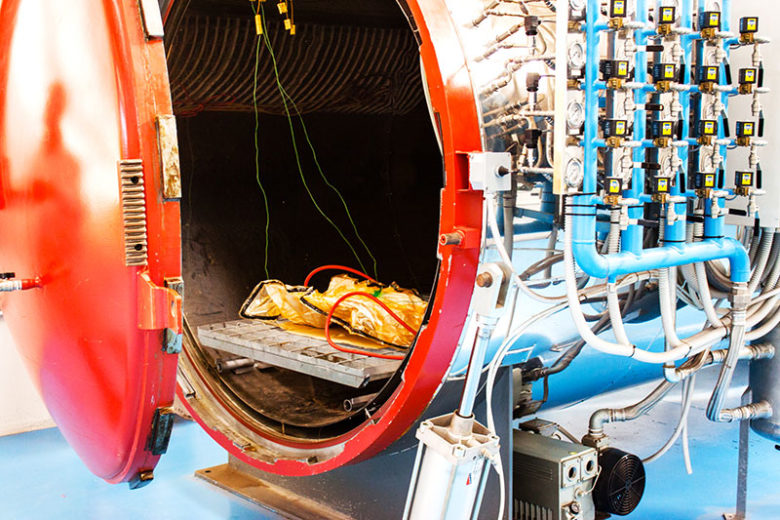

EPI team is riding this trend, aware of evolution of technologies and materials, but at the same time with strong technical skills and a long experience in innovative production plants. Our company produces carbon fiber items and composite materials components.

From horse-riding saddles to luggage, passing trough furniture-design sector, our technical office studies and tests constantly new solutions for different sectors, customizing them on clients’ needs.