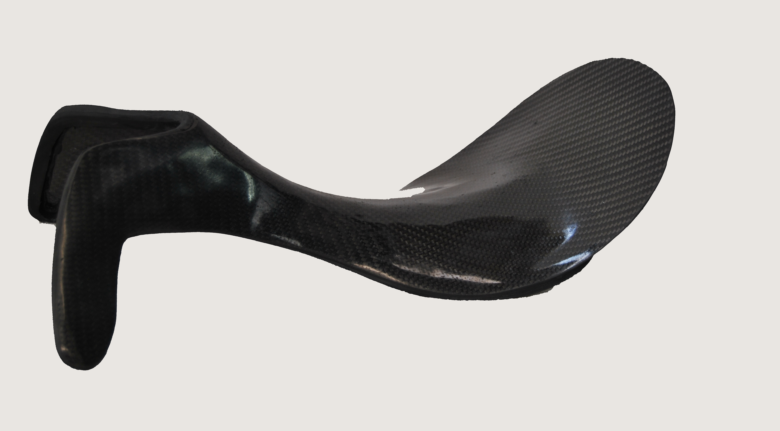

Automotive

The automotive sector has been using composite materials for years, especially in high-end productions.

We produce components for car and motorcycle bodywork, accessory parts, for individual projects or for mass production.

Based on the specific request we study customized projects and support our customers in all phases of product development.

Contact us for more information