NEW MATERIALS AND PRODUCTION PROCESSES FOR INDUSTRIAL DESIGN – MAY 17th 2018 – POLITECNICO BARI

For the cycle of meetings “Le imprese guidate dalle idee“, the conference “NEW MATERIALS AND PRODUCTION PROCESSES FOR INDUSTRIAL DESIGN“, promoted by ADI and Politecnico di Bari, was held last May 17th by some members of the EPI team, production and marketing specialists.

The lecture ( NEW MATERIALS AND PRODUCTION PROCESSES FOR INDUSTRIAL DESIGN ) which is part of a series of meetings promoted by ADI Puglia and Basilicata in the territory of competence, was held at the Politecnico of Bari, DICAR department, coordinated by Professor Rosanna Carullo and saw a large participation by students in the courses of design, architecture and engineering.

In addition to Professor Carullo, coordinator of the degree course in Industrial Design at the Politecnico of Bari, who introduced the meeting, spoke Antonio Labalestra, professor of history of design at the same university, who described the historical context of innovation, Giacomo Ventolone, EPI Marketing Specialist, describing the theme of Design and marketing as an economic lever in companies, and Tonino Rossetti, EPI Production Area, who was entrusted with the specific theme of the meeting: NEW MATERIALS AND PRODUCTION PROCESSES FOR INDUSTRIAL DESIGN.

The event led by Roberto Marcatti, president of ADI Puglia and Basilicata, starts from the awareness that design innovation is based on the availability of new materials and new production processes, and it is necessary that marketing be integrated in this process to understand the direction in which to direct communication and distribution of new products.

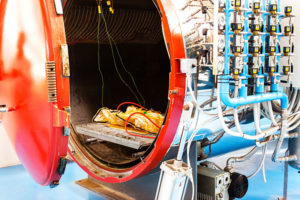

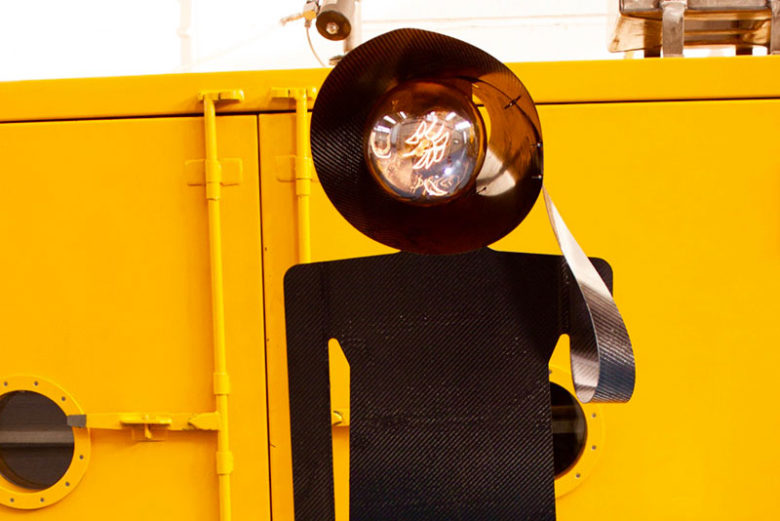

In the furniture-design sector, the use of composite materials aims to lighten the finished product, at the same time improving its mechanical and aesthetic characteristics, as well as giving it a distinctive design. A lightness that translates into greater ease of use and handling both in the warehouse and at home.

EPI, a company specialized in the processing of carbon fiber, designs and manufactures composite components for various industrial sectors. EPI has recently collaborated with several companies in the furniture industry, for the design and construction of components and structural parts, made of carbon fiber. Aerospace-derived technology blends with craftsmanship and design giving life to unique objects, which bring a still little-known material, such as carbon fiber, into everyday life!

The audience of students, and not only, showed a strong interest and participation.

The meeting “NEW MATERIALS AND PRODUCTION PROCESSES FOR INDUSTRIAL DESIGN” has highlighted numerous possibilities for collaboration which, precisely on the study of materials and processing processes, finds a convergence between the fields of the engineering sciences and design, sectors that already collaborate within the course of studies in industrial design.

This is also highlighted by Professor Carullo in her commentary on the event: “The meeting organized by the ADI with the collaboration of the course in Industrial Design at the Politecnico of Bari was an opportunity for a comparison between universities and production excellences of our Region. There are numerous topics of in-depth analysis, first of all the use of innovative materials on one side experimented on traditional product types, on the other hand to be continually tested in their multiple application possibilities, in search of their own aesthetical language.From this point of view, the importance of dialogue between the disciplines of design and of design history and engineering disciplines has emerged, a dialogue that the course of study constantly fosters also at an educational level and which can be found in the relationship with the companies of the territory its best field of experimentation, in a virtuous circle between research, teaching and innovative companies that the Adi in recent years constantly promotes “.

The valuable work of the ADI emerges from these words, whose purpose is putting in synergy more actors and more skills through this type of event and “mapping the territory covered by each delegation looking for companies and professionals with to speak the same language: project, research, innovation, technology, sustainability, alternative production systems, etc. “, as Roberto Marcatti claims.

The president then goes on to say “It is a personal satisfaction and of all the members of the Delegation’s Board to see that everything can and must be done so that different worlds can talk and start working together on new projects and new strategies; the dialogue between the different skills and disciplines of design, including that of social design is top-flight. I am sure that other companies and academic institutions will also be able to collaborate with us, that have matured ,as an Association, in 60 years since our establishment ,an experience and a role of great importance representing the entire Made in Italy chain “.