COMPOSITE MATERIALS: BENEFITS AND INNOVATIONS

The use of COMPOSITE MATERIALS in the industrial and non-industrial fields has assumed considerable importance over the last few decades. In some sectors they are completely replacing metal, plastic and wood materials, thanks to their very high physical-mechanical properties that allow structural applications in various fields.

The latest generation composites provide for the application of natural fibers and bio matrices, to be more and more eco-compatible.

COMPOSITE MATERIALS: WHAT THEY ARE AND HOW THEY CAN BE USED.

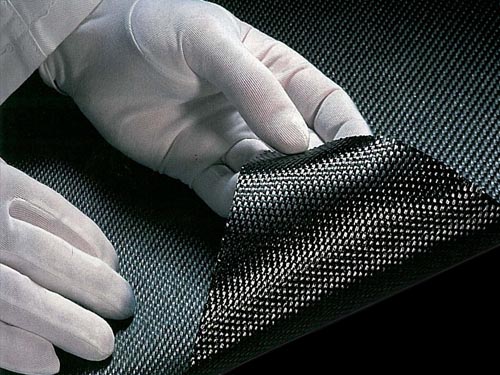

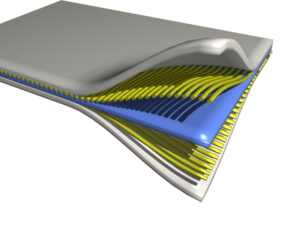

COMPOSITE MATERIALS are materials consisting of a binding matrix and a reinforcement. They are in fact obtained by the close cohesion of at least two components, whose physical and chemical characteristics are such as to make them different and mutually insoluble and therefore separate from one another. These elements are called, fiber (or reinforcement fabric) and matrix.

The matrix is the “glue” that holds the reinforcement together and protects it from the effects of the environment, also allowing to distribute the external loads inside the material and in the reinforcement. Reinforcement is a generic term for fibers, flakes or particles dispersed within the matrix.

Composite materials enable the construction of lightweight, resistant and energy-efficient structures that can be used in a wide variety of applications. In general they are used when it is required the containment of the masses of a structure or, while maintaining a high structural integrity, as well as the possibility of realizing very integrated and small dimensions. The lightness of the composites and the possibility of creating complex aerodynamic shapes allows a saving in weight and size, not obtainable with other existing technologies.

This is why the use of composite materials continues to grow in many applications.

The aeronautical and aerospace sectors represent reference sectors and are at the forefront of the use of composite materials. In the automotive industry they are mainly used to increase energy efficiency.

In some fields composites have already almost entirely replaced traditional materials, such as sports equipment for racing and wind turbines. The nautical industry also uses ever more quantities of composite materials.

More and more frequent are the less “conventional” applications, related to common sectors such as design, luggage and even accessories and item for the table!

MANUFATURING PROCESSES

The use of composite materials requires different technical and economic evaluations, in fact unlike metals or other traditional materials, they require the use of processes and methodologies, which even if applied on an industrial and production scale, have relevant time and cost of realization.

There are different methods for the production of composite materials.

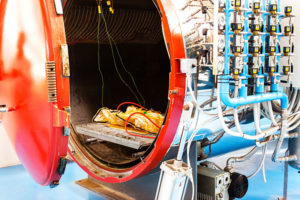

One of the main ones, as well as that used in the aeronautical field, is the autoclave process, since it guarantees the best mechanical characteristics on the finished product.

This processing is usually used to treat carbon fibers or kevlar. First, the layers of fibers of the desired length are cut; subsequently these are stacked and glued. These blocks are then inserted into an autoclave, where they are subjected to temperature and pressure programs, at the end of which the hardened laminate is obtained. In this process it is very common to use prepreg (resin impregnated fibers), which guarantee structural homogeneity to the composite.

TYPES OF COMPOSITE MATERIALS

There are many types of composite materials. The first distinction divides the fibers and the matrices into two macro areas, according to whether these are natural or synthetic.

The most famous types of synthetic fibers are certainly the CARBON FIBER, the ARAMID FIBER (KEVLAR) and the GLASS FIBER .

Alongside to these, there are the synthetic matrices: THERMO-DURING POLYMERS, EPOXY / POLYESTER, THERMOPLASTIC POLYMERS, POLYETHYLENE

Since the first products in carbon and thermosetting resin appeared for the first time on the civil market, science has made progress in the world of composites; today, other types of materials are available with alternative technical and functional characteristics compared to traditional composites.

Particularly interesting is the impregnation of natural fibers with thermoplastic resins of bio derivation that allows to obtain natural products ecofriendly very requested by the current market

The natural composites, that is constituted by at least one element of natural derivation, are currently of particular importance. Today, in fact, alternative sources are available; this is the case, for example, of so-called “green” reinforcements, such as hemp, linen or bamboo fibers.

BENEFITS

The use of composite materials allows to create products with characteristics previously impossible or simply give new life to a mature product.

The benefits deriving from their application are numerous, including:

- MECHANICAL RESISTANCE

- CHEMICAL RESISTANCE

- SHAPE STABILITY

- LIGHTNESS

- VERSATILITY IN THE REALIZATION OF GEOMETRIES

- ELASTICITY

- LONG LIFE TIME

In addition to structural efficiency, composite materials can also be more intelligent, more functional and versatile than traditional ones. The combination of new features in composites is considerably easier than metals and the only obstacle is the boundaries of imagination.

Composite materials will make tomorrow’s world an increasingly functional place to live!

Discover more www.epigroup.eu

FOLLOW US ON

FACEBOOK : https://www.facebook.com/pg/EPIcarbonfiber/%22

TWITTER : https://twitter.com/EpiCarbonFiber/

LINKEDIN: https://www.linkedin.com/company/epi-carbon-fiber-manufacturing/