CARBON FIBER FURNITURE : TECHNOLOGY MEETS DESIGN!

Furniture-design is a sector that constantly evolving and always open to experimentation of new materials. One of the latest trend is the creation of carbon fiber furniture, an innovative material which well suits as aesthetic and structural component in high-end design items.

This material, still unknown to the genral pubblic, until few years ago was applied almost exclusively in high-tech sectors, like the aerospace and automotive, expanding afterwards to the construction.

Less frequet, but more and more widespread, is its use in furniture and design.

At salone del mobile 2015 in Milan, carbon fiber furniture was one of the major innovations introduced and an increasing number of international designers are approching this material, as well as the leader companies employ it to innovate existing products or to launch new forniture solutions.

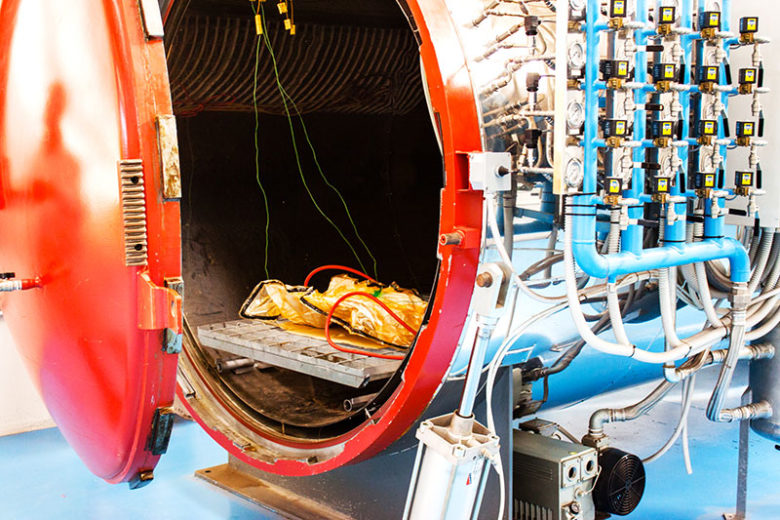

Carbon fiber is an higly performing material, with mechanical properties even higher than steel, which permit to obtain very resistant structures, able to support extreme stresses.

This combines with its great lightness and ductility, that allow to realize forms never experienced, with a unic visual effect.

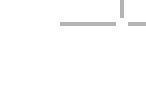

Even us of EPI are testing the design and creation of carbon fiber furniture.

Our technical office is able to offer customer consultancy starting from analyzing the existing problems in a product and then studying new and sustainable ad hoc solutions.

Carbon fiber furniture, and more generally the uso of composite materials in design , brings a lot of benefits:

- high customization

- elegant and original finishes

- maximum lightness

- high resistance to stresses, chemical and atmospheric agents

This features are well suited to the construction of tables, chairs, lighting object, outdoor furniture, and everything in which innovation, technology and creativity are key elements to realize unic items.

For more information about our carbon fiber furniture components and composite materials manufacturing please write us or visit our web site:

info@epigroup.eu –

www.epigroup.eu/EN